Propylene Glycol production with BONSILAGE CORN+

Read how BONSILAGE CORN+ treated corn silages produce significant amounts of propylene glycol.

Corn silage harvesting creates one of the most exciting and at the same time challenging periods of the year. In order to prepare for another successful silage season, we are looking back at corn silage parameters produced last year. We ask ourselves: “How did we perform?”.

As part of our routine service, we sampled several 2019-corn silages in spring 2020. One particular focus was on corn silages treated with our BONSILAGE CORN+ inoculant. In this context, we did not only look at nutritive and digestibility aspects but also at BONSILAGE CORN+ typical fermentation patterns.

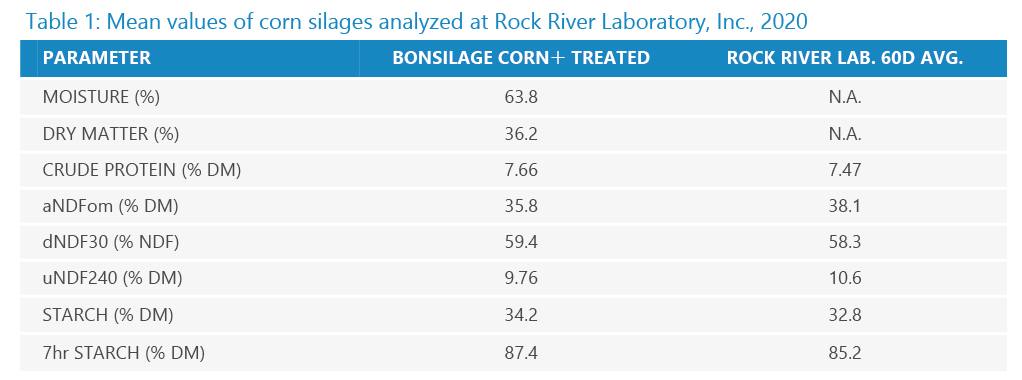

The results of our survey are displayed as mean values of sampled BONSILAGE CORN+ treated corn silages (n=22) in Table 1. They got compared to a “60-day-average” which is provided by Rock River Laboratory (comparison base May 13, 2020). Mean values for digestibility parameters such as NDF30 and 7hr starch digestibility appear to be approximately 1 to 2 percent points higher than the 60-day-average, respectively. Moreover, uNDF240 values of BONSILAGE CORN+ treated silages are app. 1 point lower than the comparison base.

BONSILAGE CORN+

- Inhibits yeasts and molds and protects against reheating

- Reduces the risk of ketosis by producing propylene glycol

- Ensures high feed intake

- 500,000 CFU/g fresh forage

Fermantation profile

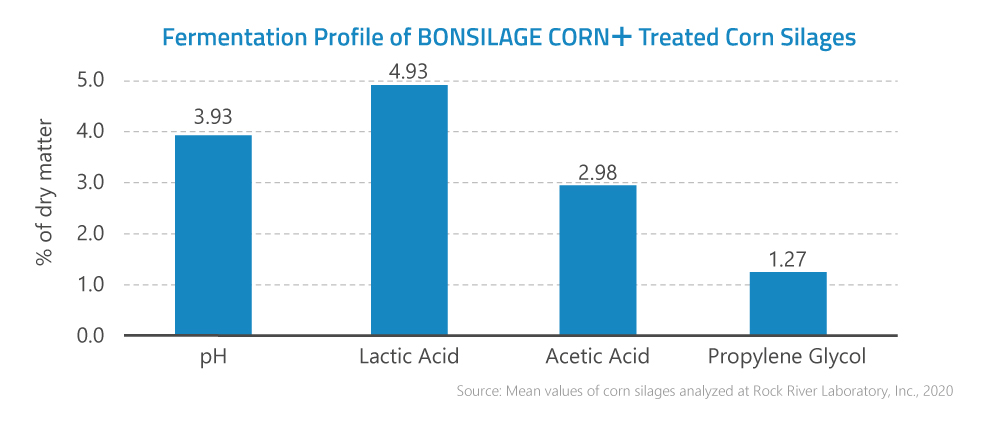

The fermentation profile of sampled corn silages, characterized by pH, lactic acid and acetic acid, is also illustrated in mean values (see Figure below). With regard to these variables, analyzed levels are typical for corn silages treated with an inoculant containing homo- and heterofermentative lactic acid bacteria. Sufficient lactic acid for a rapid pH drop was produced and thus the inactivation of undesired microorganisms as well as enzymatic degrading processes were achieved.

Furthermore, we found adequate amounts of acetic acid that indicate high aerobic stability. The efficacy of acetic acid produced by Lactobacillus buchneri on the suppression of yeast and mold growth has already been proven in numerous studies. In addition, we analyzed sampled silages for 1.2 -Propanediol, the chemical term for propylene glycol (PG). It is produced by the L. buchneri strain contained in BONSILAGE CORN+. PG, commonly used as a drench for cows suffering from ketosis, is a naturally produced metabolite of our inoculant.

Feeding silages containing significant amounts of PG to transition cows may help to reduce energy deficit induced subclinical ketosis post – parturition, and thus have a positive influence on performance and health status during early lactation.

BONSILAGE CORN+ is a premium treatment for corn or sorghum silage, creating a highly digestible feed source for animals.