Don’t Spoil Your Summer Silage Management

Warm weather is a hot time for rapid yeast growth. Here’s how to mitigate the impact of spoilage when the thermometer rises.

Spoilage is a problem that makes farmers turn up their noses all year long, but it can be especially problematic during the hotter months. When temperatures and humidity rise, yeast grows rapidly, especially on the exposed silage face. Here are some tips to mitigate the rise of yeast and the prevalence of spoilage in your silage.

When building your pile, packing weight shouldn’t be overlooked. Packing density is inversely related to oxygen penetration rate through the silage face, limiting the growth of the microorganisms that cause spoilage. To limit those microorganisms, your packing density should be a consistent 15-16 lb of DM/cubic foot or higher. Check out our blog for more tips about packing density.

To minimize spoilage, feedout rate should be at least 6 to 8 inches but really should be nearly double that minimum during summer months. While a minimal feedout rate can limit spoilage during the winter, during the summer we should increase to 12 to 14 inches a day. Here’s more about optimal feedout rates.

Sealing your pile quickly and completely is important because without an immediate and thorough seal, nearly half your crop can be at risk of spoilage. But continually monitoring your plastic is nearly as important as the initial seal. Regularly checking your whole pile for tears in the plastic or other uncovered areas can save you a lot of silage

Also, don’t cut back too much plastic during feedout to minimize silage surface area that gets exposed to oxygen.

We stressed it on our recent blog about spoilage prevention and we’ll stress it now: You must inoculate your forage to truly prevent spoilage. Heterofermentative inoculants are designed to limit yeasts and mold growth, and bonsilage products are proven to help avoid losses of your hard-earned feed.

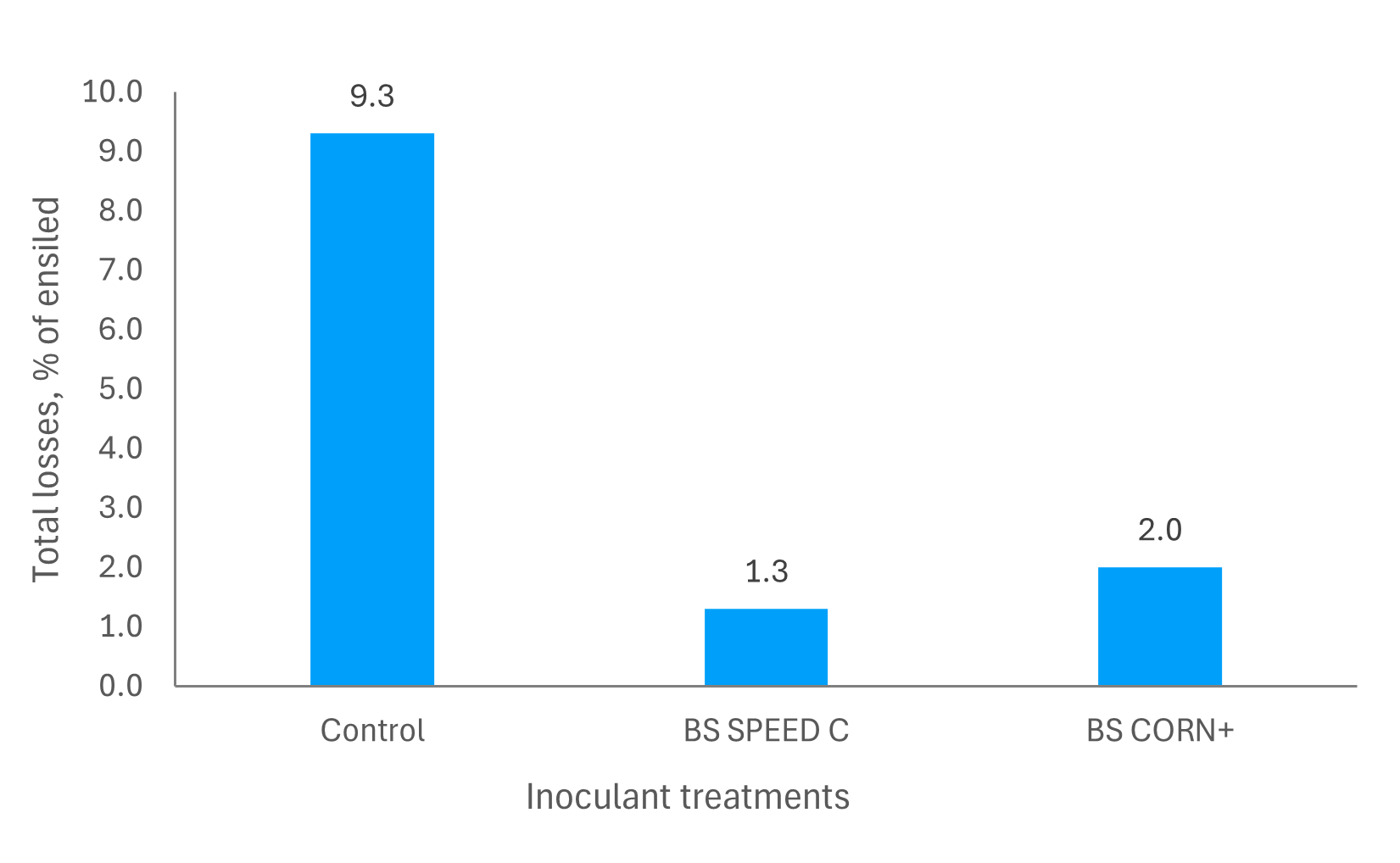

Our 2024 study shows that losses in uninoculated silage can be more than four times what they are if you inoculate with bonsilage SPEED C or CORN+.

Figure 1 describes the sum weight losses during fermentation (30 d) and aerobic exposure (10 d) in laboratory silos untreated or treated with BS SPEED C and BS CORN+. Aerobic stability tests and aerobic losses experiments are usually conducted over 240 h (10 d), which is a standard research procedure that indicates “shelf-life” of silages in the field. Even if the numbers cannot be directly transferred to “field silages,” they clearly show that acetic acid production by desirable microbes and at the right time can really make a difference in overall silage losses.

If you have any further questions about spoilage prevention during the summer (or any other time of year), set up a chat with your bonsilage expert today!