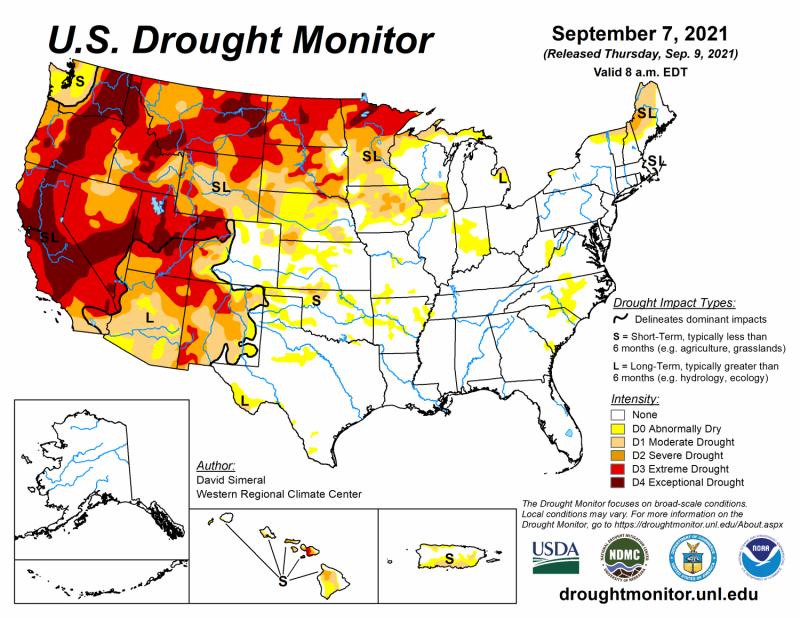

Impact of the droughts across the US

The current droughts across the United States have a huge impact on the agriculture. Many areas of the United States continue to fight drought conditions. Moreover, they have an effect on forage availability and quality. Read about managing your silage under such difficult conditions.

What should be considered before harvesting drought stressed corn?

In order to maintain the silage quality, especially in dry periods, the following factors can be taken into account.

- When plants start to dry down, the DM content can decrease rapidly.

- Drought stressed dry down rapidly when days are hot, dry and windy. Therefore, plants are not actively growing.

- Determining DM

- Using a moisture tester is the most accurate method.

- Chop up 15-20 plants (randomly from throughout the field) into silage particle size.

- Historically, kernel milk line has been used as a visual indication of whole plant dry matter. However it has been found to not be as accurate.

- It can be used as a basic of when to start testing with a moisture tester.

- Using a moisture tester is the most accurate method.

- Reduce chopping length

- If harvested drier than recommended, reduce the theoretical chop length to aid in packing.

- Kernel development

- Plants that have kernels forming allow to develop further to increase dry matter and silage quality.

- Plants with no kernel development (barren plants) should be harvested as soon as plant moisture is within range.

- The color of the plant itself is not a good indicator for DM and when it is ready to be harvested.

- When plant growth is impaired during drought conditions, nitrates will accumulate. High nitrates are toxic to both cattle and humans.

- Ensiling reduces nitrate levels up to 50%. It is still important to allow forage material to go through the entire fermentation process.

That takes at least 4 weeks, and then test material before being added into the ration. - Avoid feeding green chop.

- This varies a lot.

- If ensiled properly, can yield a suitable forage.

At the end, it is important to protect your investment.

Drought conditions affect overall yields and quality. We cannot do anything to increase yields but we can use an inoculant like BONSILAGE. With silage additives we protect our harvest. In this manner cows get the highest quality feed given the situation.